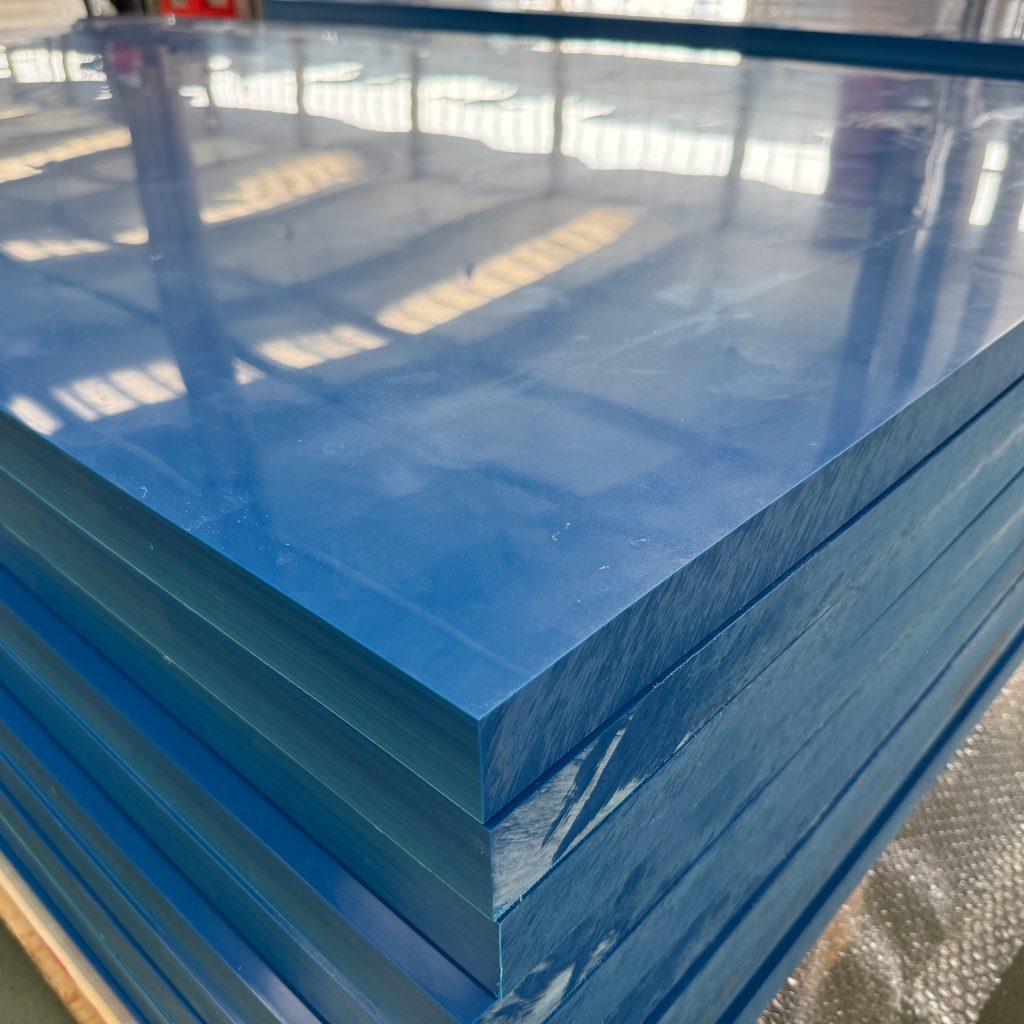

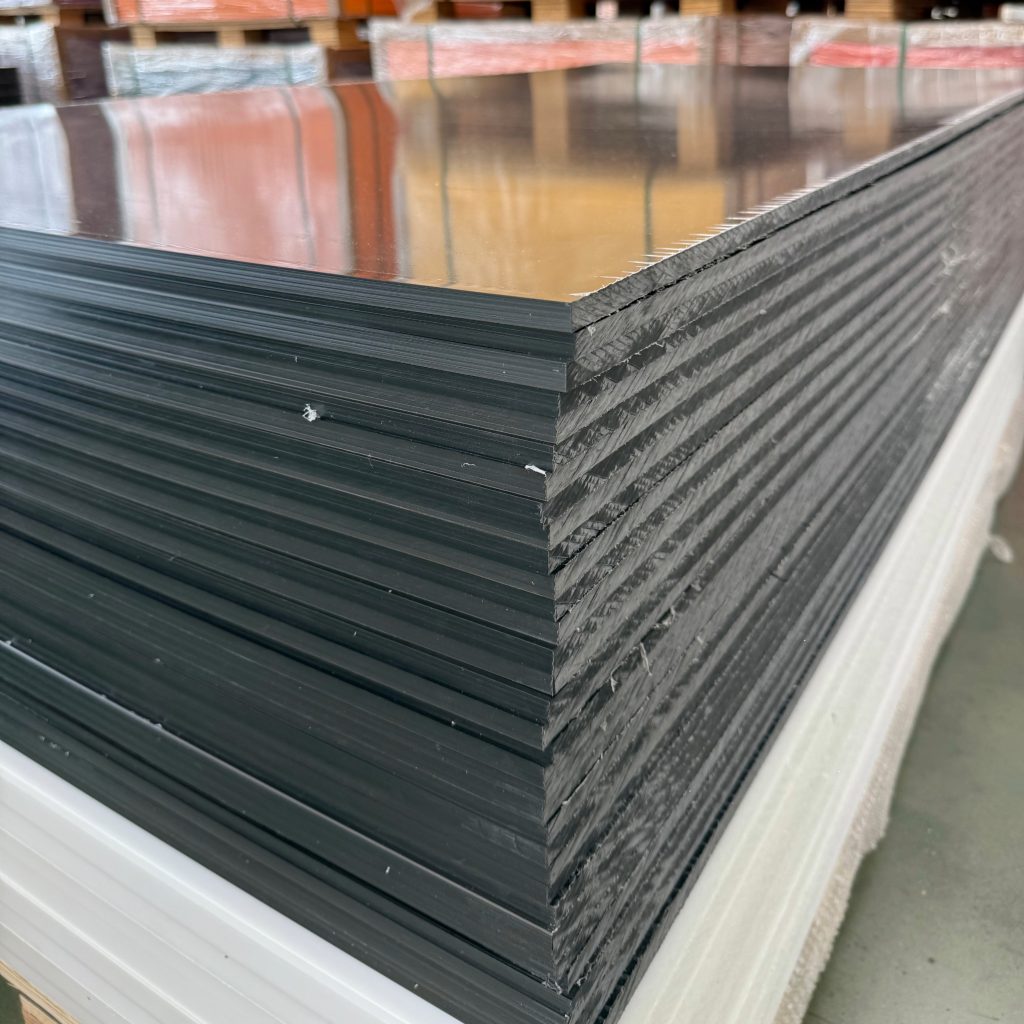

Ultra High Molecular Weight Polyethylene (UHMWPE)

& High Density Polyethylene (HDPE) Products

What is UHMWPE?

Ultra high molecular weight polyethylene (UHMWPE) is an extremely tough material that is used in countless applications due to its superior wear resistance, high abrasion properties and ability to tolerate high stress and temperature environments.

The most common industries that utilize these products:

- Mining

- Construction

- Manufacturing

- Civil engineering

- Earthmoving

- Transport

- Automotive

- Food processing

- Chemical

- Low friction

- Chemical resistance

- Low coefficient of friction

- High stress resistance

- Superior sliding

- Impact resistance

- Abrasion resistance

- Lightweight

Common uses of the UHMWPE products:

- Truck and tray linings

- Bins and hoppers

- Chute liners

- Mechanical bearings

- Gears & rollers

- Wear parts

- Material handling

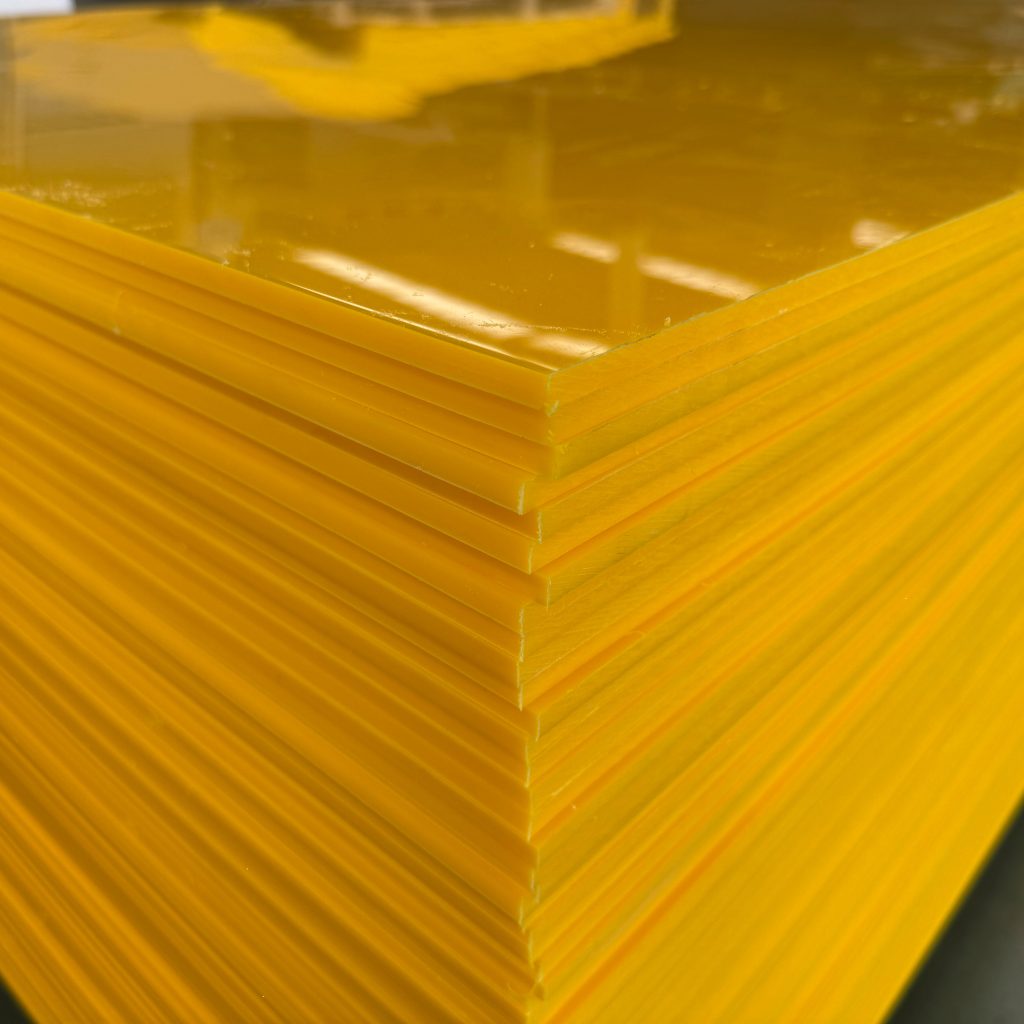

What is HDPE?

High density polyethylene (HDPE) is one of the most popular materials used in manufacturing due to its ability to be recycled, and environmentally stable form as it produces zero harmful fumes. It has an exceptional resistance to oil, moisture, chemicals, fading and warping and can be moulded into practically any shape whilst still offering a cost effective solution.

HDPE is most commonly used in the below markets:

- Food services

- Golf courses

- Mining and construction

- Municipal parks and recreation

- Public venues

- Automotive

- Manufacturing

- Resistant to moisture and chemicals

- High impact resistance

- Lightweight

- High vibration damping

- Excellent wear resistance

- Mining pipes & tubes

- Chemical and liquid tanks

- Playground equipment

- Chute & bin liners

- Marine pile guards

- Machinery bumpers